On June 13, 2018, the National 863 Program "key technology of high strength and toughness medical implant materials" project acceptance meeting was held in Beijing railway building, and the acceptance expert group was composed of High Tech Department of Ministry of science and technology, high tech center and acceptance experts. At the meeting, the expert group reviewed the acceptance data, listened to the report, and held questions and discussions. Finally, they reached a consensus that the project achieved remarkable results, and all indicators met the assessment requirements, and agreed to pass the acceptance. This also means that China's last batch of 863 plans has gradually come to an end.

The national high technology research and development plan (863 Program) was launched in March 1986. It is a basic research-oriented national plan led by the government. It aims to improve China's independent innovation ability, adhere to the strategic, cutting-edge and forward-looking, focus on the research and development of advanced technology, plan the integrated application and industrialization demonstration of high-tech, and give full play to high-tech to lead future development The leading role of exhibition. The implementation of the "863 Plan" is an important strategic deployment of the Communist Party of China to invigorate the country through science and education, and has laid a more solid foundation for China to occupy a place in the world's high-tech field.

In December 2014, the State Council issued the "plan on deepening the management reform of the central financial science and technology plan (special projects, funds, etc.). According to the national strategic needs, the government's scientific and technological management functions and the law of scientific and technological innovation, the State Council integrated the science and technology plans (special projects, funds, etc.) managed by various departments of the central government into five types of science and technology plans (namely, the National Natural Science Fund, the national science and technology major special projects, the national science and technology major special projects, the national science and technology National key R & D plan, special project of technology innovation guidance (Fund), base and talent special project). Among them, 863 plan, 973 Plan and national science and technology support plan were integrated into national key R & D plan. The first batch of guidelines was released on February 16, 2016, which means that 863 program has become a historical term. As a national high-tech enterprise actively promoting technological innovation, chuang'erbio participated in the implementation of the last batch of 863 Program projects in China, and witnessed this historical moment.

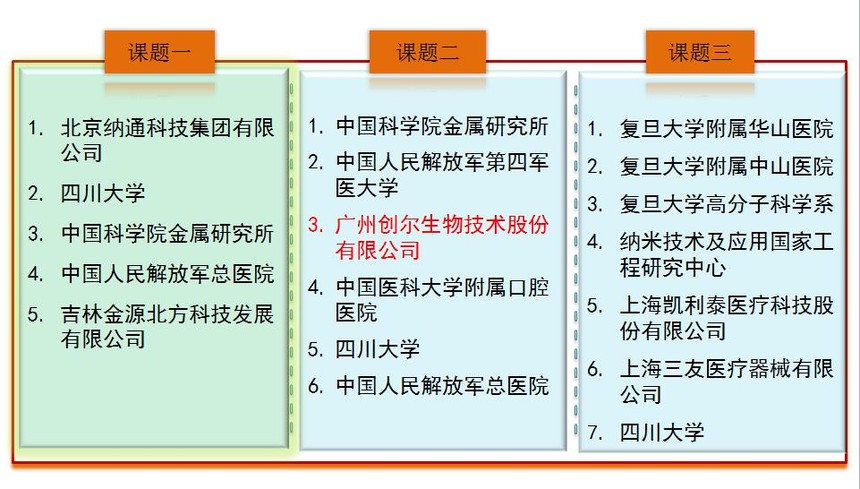

The project of "key technology of high strength and toughness medical implant materials" is led by Beijing natong Technology Group Co., Ltd. and Professor Wang Yan of the General Hospital of the people's Liberation Army is the project leader. The project consists of 3 subjects, completed by 18 participating units and 203 participants. As a project participant, Guangzhou chuang'er Biotechnology Co., Ltd. participated in the second project "research and development of high strength and toughness porous titanium artificial bone material", and undertook the research task of "preparation of collagen coating on the surface of high strength and toughness porous titanium". In this study, medical collagen coating was used to modify the surface of titanium alloy, and the key technology and performance control method of collagen coating on the surface of high-strength and tough porous titanium were investigated, and the structure, properties and the effect of collagen coating on bone defect repair were studied.

Project member units

The project lasted three years from April 2015 to March 2018. It has applied for 46 invention patents, published 45 SCI papers, formed 6 enterprise standards and 1 industry standard, and developed new products including absorbable nail plate system, self reinforced bone rod, sports medicine belt anchor, bone filling device, porous spinal fusion device, bone trabecular acetabular cup, suspended artificial ligament and other new products It covers bone defect repair, tendon bone repair, soft tissue repair and other fields. Among them, Guangzhou chuang'er Biotechnology Co., Ltd. has applied for 5 national invention patents and 1 PCT, forming two enterprise standards. The collagen coating prepared has stable structure and excellent performance, without cytotoxicity, intradermal reaction, acute systemic toxicity and sensitization. The research results have been unanimously recognized by the cooperative units and expert groups.

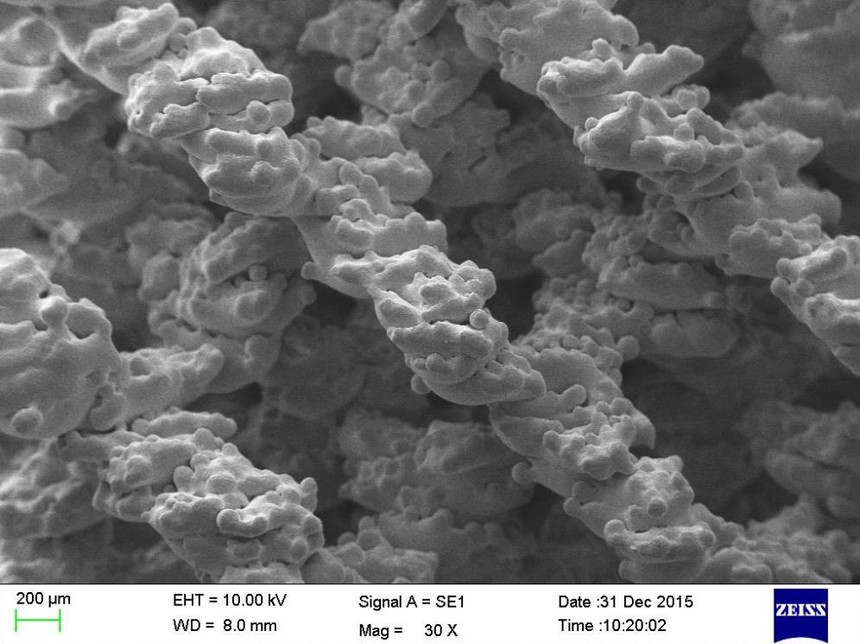

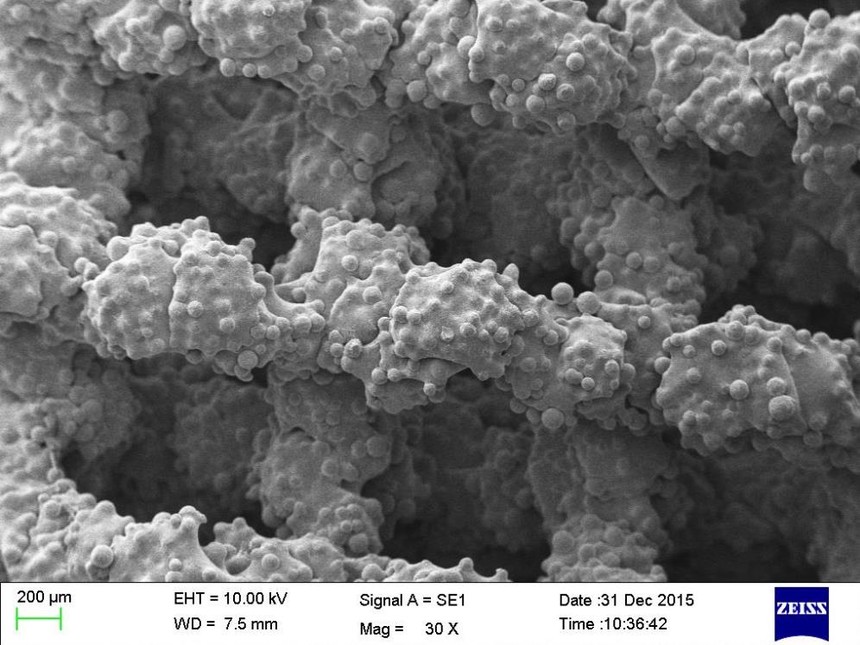

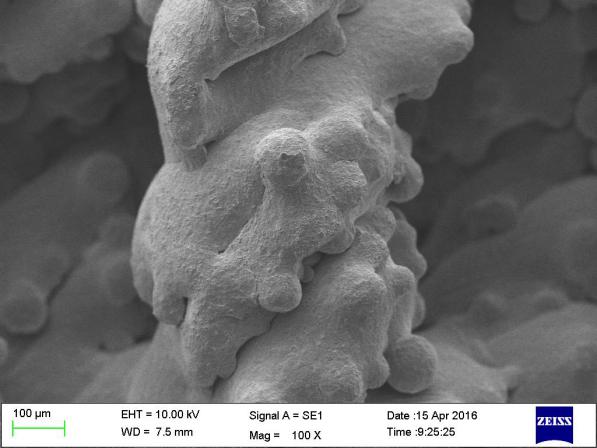

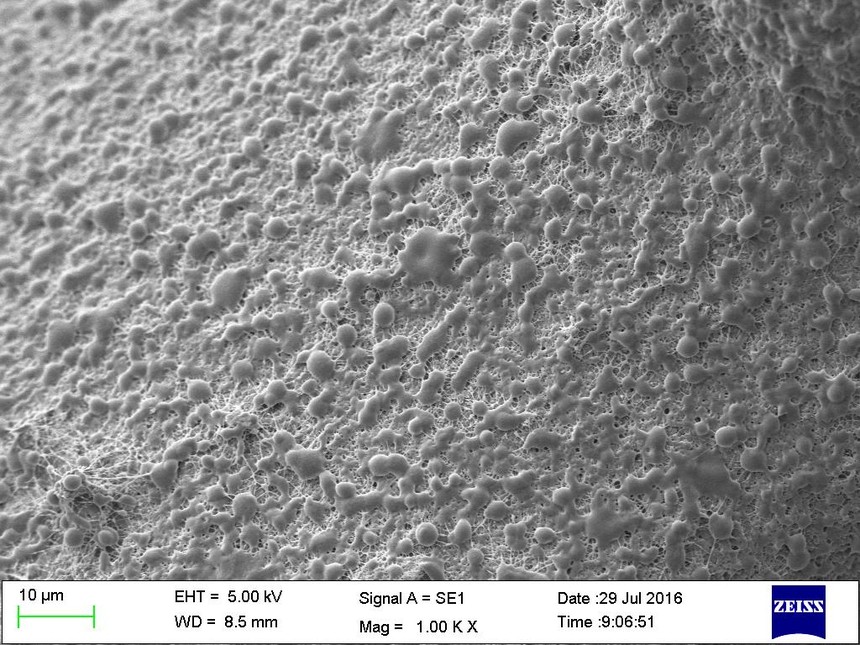

Titanium alloy bracket and micro arc oxidation titanium alloy bracket

SEM image of collagen coated porous titanium alloy

As a leader in the domestic collagen industry, chuang'er bio focuses on the research, development, production and operation of medical collagen and its related medical products, and makes intensive efforts in the fields of Dermatology, burns, obstetrics and Gynecology, orthopedics, dentistry and medical cosmetology. With the support of the National 863 program, medical collagen and high strength and toughness porous titanium alloy artificial bone are combined to improve the biocompatibility of titanium alloy by utilizing the high biological activity of collagen, which has a good market application prospect. The implementation of the project also strengthened the communication and cooperation between the R & D center and domestic universities and scientific research institutes, expanded the company's technical fields and business channels, and laid a solid foundation for the continuous development of collagen based medical materials and products.

Clean production workshop of the company